The Process of Making High Strength Concrete Piles: Insights from a Korean PHC Pile Factory

High-strength concrete piles are a critical component in the construction of robust and durable structures. In this article, we delve into the intricate process of manufacturing these vital elements, focusing on the operations at a Korean PHC (Pre-stressed High-Strength Concrete) pile factory. This factory showcases the precision and expertise required to produce high-strength concrete piles that meet the demanding standards of the construction industry.

Step 1: Preparing the Concrete Mix

The journey of a high-strength concrete pile begins with the preparation of the concrete mix. This mix is carefully formulated to achieve the desired strength and durability. The blend typically includes high-quality cement, fine and coarse aggregates, water, and specific admixtures that enhance the concrete’s performance. The proportions of these materials are meticulously calculated to ensure the mix can withstand the stresses it will face during use.

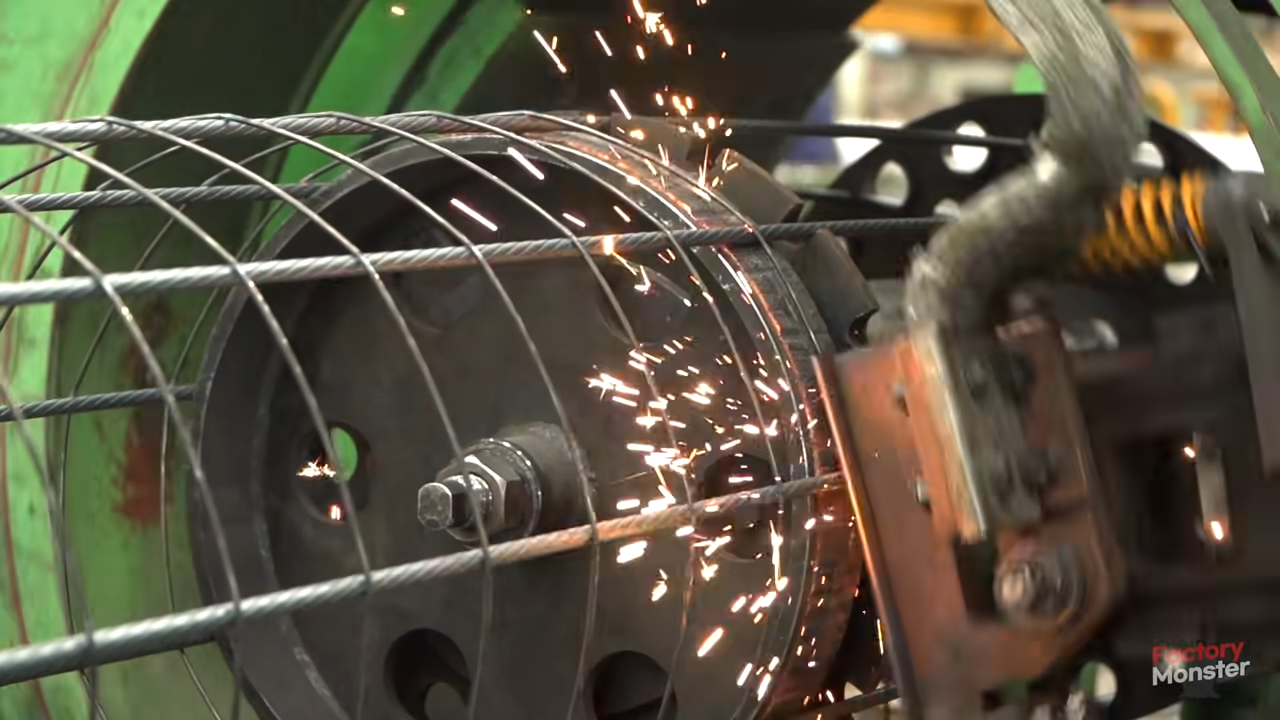

Step 2: Molding and Pre-stressing

Once the concrete mix is ready, it is poured into specially designed molds. These molds are configured to give the piles their final shape and size. Pre-stressing is a crucial part of this process. Steel wires or strands are placed under tension within the molds before the concrete is added. As the concrete hardens, these pre-stressed wires provide additional strength, enabling the piles to bear heavy loads once in use.

Step 3: Steam Curing

After the concrete is poured and set, the piles undergo a steam curing process. This involves subjecting the piles to controlled heat and humidity, which accelerates the curing of the concrete. Steam curing not only speeds up the production process but also enhances the strength and durability of the final product. This step is essential in achieving the high-strength characteristics that PHC piles are known for.

Step 4: Demolding and Quality Inspection

Once the curing process is complete, the piles are carefully removed from their molds. This stage requires precision to avoid any damage to the newly formed piles. After demolding, each pile undergoes a thorough quality inspection. This inspection ensures that the piles meet the required specifications and are free from any defects. Only those that pass this rigorous check are deemed fit for use in construction projects.

Step 5: Storage and Transportation

The final step in the process is the storage and transportation of the finished piles. The piles are stored in a controlled environment to prevent any damage before they are shipped to construction sites. Proper handling during transportation is also crucial to maintain the integrity of the piles until they reach their final destination.

Conclusion

The production of high-strength concrete piles is a meticulous process that requires attention to detail at every stage. From the preparation of the concrete mix to the final inspection, each step is designed to ensure that the piles can perform under the most demanding conditions. Korean PHC pile factories exemplify the level of expertise and precision needed to produce these essential components, contributing to the construction of safe and stable structures worldwide.